| Reportage sulla visita al laboratorio innovativo indoor di stoccafisso Nofima di Oslo realizzato da Tiziano Biasioli e Vasilisa Razdayvodina |

|

|

|

Visita

al laboratorio Nofima Visit to Nofima laboratory Oslo - Norway |

|

|

|

|

La produzione indoor di

stoccafisso

Nordahl Anthonisen di

Athena Seafoods AS di Bergen ebbe l'idea

iniziale:

Per questo motivo ha

coinvolto in un progetto UE importanti

aziende e istituti di ricerca europei,

insieme al ricercatore John-Erik Haugen.

I risultati della ricerca dimostrano che

è possibile produrre pesce essiccato

all'interno, partendo dal merluzzo

fresco senza teste ed intestini: la

materia prima utilizzata per la

produzione tradizionale esterna dello

stoccafisso.

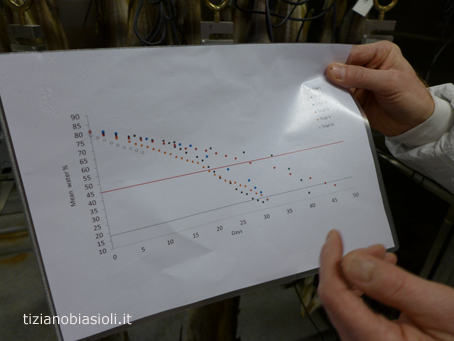

Oltre all'utilizzo di materie prime tradizionali, il lavoro di sviluppo riproduce le condizioni meteo ottimali per l'essiccazione tradizionale all'aperto. Mentre l'essiccamento esterno tradizionale su rastrelliere richiede circa quattro mesi, Haugen ha bisogno di meno di un mese per la produzione di pesce di alta qualità essiccato indoor. Il progetto europeo ha elaborato anche calcoli di costi-benefici e questi dimostrano che il nuovo metodo è economicamente sostenibile. L'azienda alimentare italiana Il Ceppo ha 80 anni di esperienza nel settore baccalà/stoccafisso. Il personale della società ha partecipato al progetto e ha valutati sia l'aspetto sia l'odore del pesce essiccato al chiuso. Il Ceppo ha anche effettuato indagini presso i consumatori in Italia; sono state effettuate “prove al buio” di pesce essiccato al chiuso e all'aperto, facendo assaggiare piatti della tradizione italiana.

"Questi test iniziali

indicano che il prodotto sperimentale è

di alta qualità che i piatti a base di

stoccafisso essiccato indoor sono

altrettanto buoni come quelli a base di

prodotti tradizionali all'aperto" dice

Haugen. Un brevetto è stato applicato per proteggere il nuovo processo.

Nofima e Athena Seafoods

stanno lavorando insieme per sviluppare

ulteriormente il progetto, in vista

della sua commercializzazione. |

|

|

|

|

|

|

|

Thanks to John-Erik

Haugen, PhD, Senior researcher Nofima AS, Post Box 210, NO-1431 Aas, Address: Osloveien 1, Aas www.nofima.no

|

|

|

|

|

|

Riccardo Boscolo titolare della Gastronomia Il Ceppo di Vicenza visita l'impianto di essicazione indoor accompagnato da John-Erik Haugen - Nofima Riccardo Boscolo owner of Gastronomy Il Ceppo of Vicenza visit the laboratory accompanied by John-Erik Haugen - Nofima |

|

|

|

|

|

|

|

|

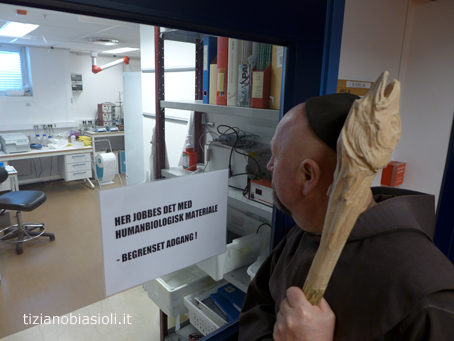

Hanno visitato il laboratorio anche i due frati della Confraternita dello Stofiss dei Frati di Rovereto: il Priore Fracasso e fra' Dolcino. Visited the laboratory Nofima also the two brothers of the Confraternita dello Stofiss dei Frati di Rovereto: the Fracasso Prior and fra' Dolcino |

|

|

|

|

|

Vedi anche il nostro magazine: www.tizianobiasioli.it e i nostri FB e siti |

|

|